Frequently Asked Questions

Small modular reactors represent one type of advanced nuclear technology that can help generate the reliable, clean electricity needed to meet future energy demand. Here are answers to some frequently asked questions about small modular reactors and nuclear development.

-

SMRs are advanced nuclear reactors that can generate between 50 and 500 megawatts (MW), about one-third of the energy of a traditional nuclear reactor. SMRs are a fraction of the size and utilize the latest advances in design to ensure safe and efficient construction and operation.

-

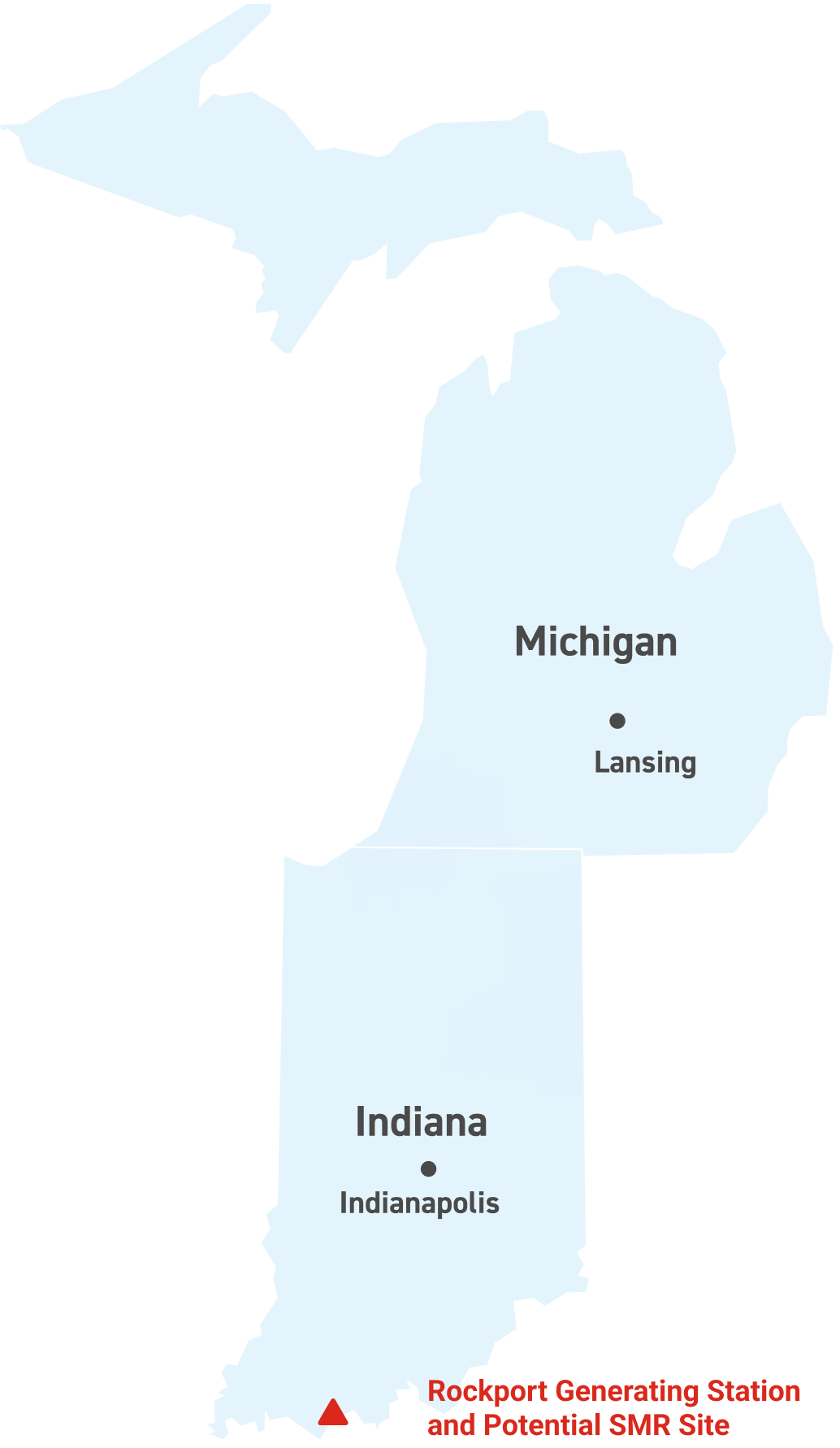

The Rockport site, owned by I&M, was chosen after a thorough evaluation of several other locations, based on the criteria set forth in the Electrical Power Research Institute (EPRI) Siting Guide for assessing new nuclear energy generation sites.

It offers many key advantages to building an SMR:

Existing Infrastructure: First, it is 4,500 acres and already has the necessary power delivery infrastructure in place making it more economical to develop.

Environmental Suitability: The site has been evaluated for its environmental impact and is deemed suitable for nuclear energy generation.

Skilled Workforce: The existing regional workforce is experienced and capable of operating and maintaining a major power plant, providing a pool of skilled labor for the project. By investing in the local workforce, the project will continue to provide a significant opportunity for skilled jobs for Spencer County and the surrounding communities.

Community Benefits: This project will enable I&M to continue supporting the local community and economy.

-

Nuclear power plants are among the safest means of generating electricity, and small modular reactor designs are simpler than traditional nuclear facilities. SMR designs take advantage of natural forces like gravity, condensation or pressure differences to keep the reactor core safe. Trained staff are on-site to monitor these systems and ensure they perform appropriately. A small modular reactor would operate under stringent regulatory oversight and include comprehensive operational safety and emergency response plans.

-

Providing our customers with reliable and low-carbon electricity at competitive rates is I&M’s priority. By pursuing federal grants, strategic partnerships, and technology-based incentives, I&M is taking steps to bring the next generation of reliable and clean nuclear energy to Indiana while minimizing cost impacts to I&M’s customers.

-

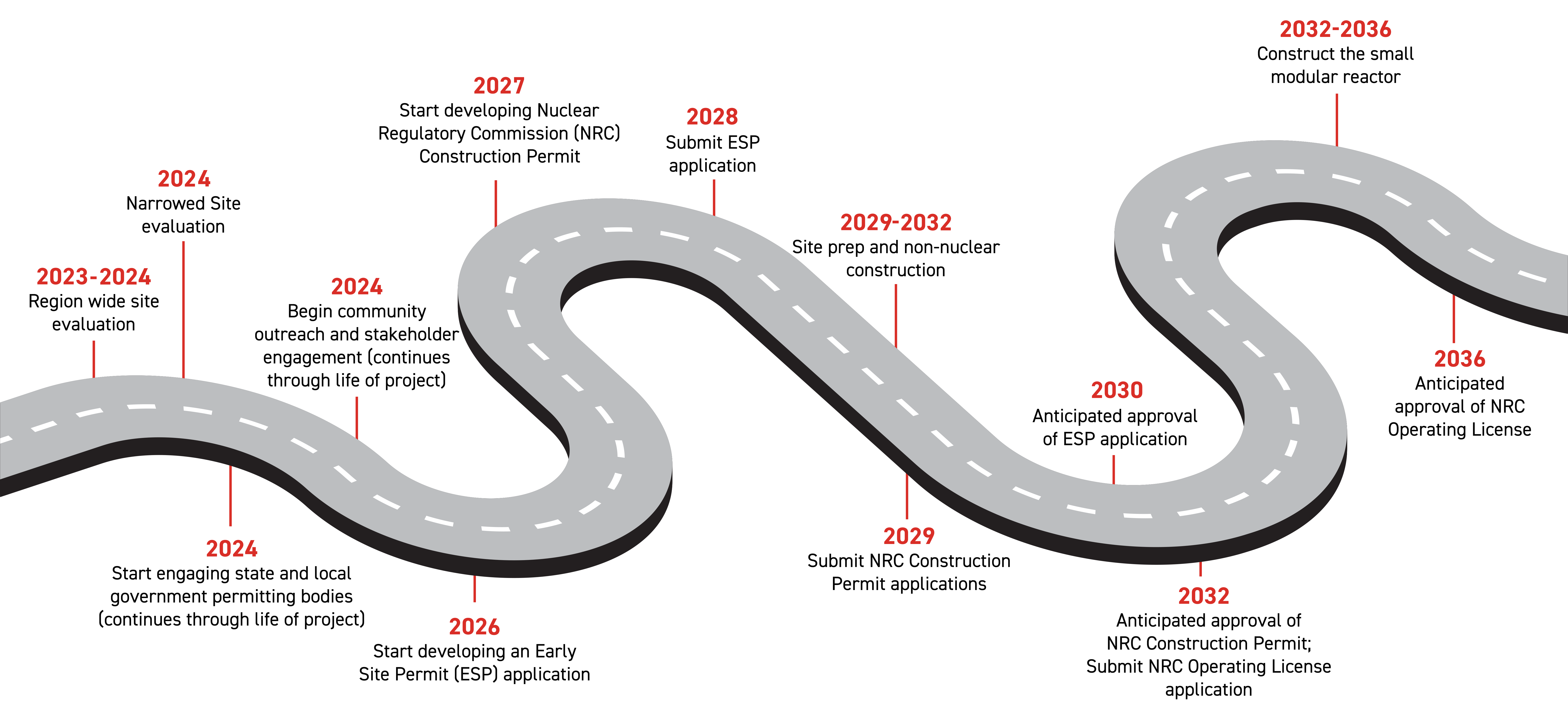

Developing an SMR is a 10-to-15-year journey with many steps along the way. I&M is in the early stages of the process and will continue to provide updates as the project progresses.

The above milestones are estimated based on best-case NRC permit and licensing timelines, subject to approval by permitting authorities, pending federal incentives, and subject to change. Read more at NRC.gov/about-nrc/generic-schedules.

-

Development of SMRs can provide significant economic benefits to communities and states. Construction typically involves thousands of employees, creating a ripple effect that spurs additional indirect and direct employment opportunities. Operation of a small modular reactor can create hundreds of jobs, spur new economic activity, promote advanced training and educational opportunities and add millions of dollars in new annual local, state and federal tax revenue. The periodic refueling process also can carry additional short-term economic benefits, including doubling the reactor's workforce with highly skilled contract workers for up to three months. In addition to the direct benefits associated with the SMR facility itself, the ability for I&M to provide customers with clean and reliable energy 24/7, 365 days a year will be an important tool to attract new businesses into I&M’s service area, which provides benefits to all I&M customers.

-

Nuclear energy is a proven clean energy technology. Nuclear power generation has been around since the 1950s and has seen massive growth globally since. It is a vital resource for successfully reducing carbon emissions while preserving reliable access to energy. According to the U.S. Energy Information Administration, in 2023, 18.6% of U.S. electricity came from nuclear power. Natural gas accounted for about 40%, followed by 21.4% from all renewable sources and 16.2% from coal. Nuclear power is the largest clean source of electricity generation in the U.S.

-

When it comes to managing spent fuel, SMRs are expected to operate in a manner consistent with conventional reactors. Currently, spent fuel is safely and securely stored at more than 70 reactor sites across the country. Spent fuel is placed in a storage pool of water to both cool and shield the material. These pools are constructed with thick reinforced concrete and steel liners and are often designed to hold all of the spent fuel produced over the planned operating life of the reactor. Once fuel is cooled in a pool and then stored in dry casks with air circulation inside concrete shielding. Utilities are reimbursed under their contract with the U.S. Department of Energy for most of the costs of long-term storage on site. Long-term storage of spent fuel on site must adhere to the NRC regulations, as existing large-scale commercial reactors do across the U.S.

I&M is experienced with spent fuel storage management, as shown in the above pictured dry storage casks at the Donald C. Cook Nuclear Power Plant in Bridgman, Michigan. The dry storage casks shown contain the majority of the spent fuel for 2.3 gigawatts and nearly 50 years of operation.